Sodium iodide crystal

Product Description

Thallium doped sodium iodide crystal (NaI:TI) is a scintillation crystal with excellent performance. This crystal is grown by adding appropriate concentration of activator thallium (Tl) to sodium iodide (NaI) as the base material, and its maximum luminescence wavelength is 415 nm, which can be well matched with the photocathode of common size photomultiplier tubes.

NaI:TI scintillator is a colorless and transparent crystal, which has basically no absorption of its own luminescence. Because of its high density, high effective atomic number, strong absorption ability and high energy resolution for X-rays and Γ-rays, it occupies an important position in radiation detection, and it is an important basic material in detection instruments for geology and mining, petroleum, coal, medical treatment, security inspection, industrial CT and environmental detection.

Introduction of NaI:TI

NaI:TI is a traditional inorganic scintillation crystal with excellent performance and good resolution of both X-rays and Y-rays, and can detect the energy and degree of X and Y-rays.

The luminous efficiency of NaI:TI crystals is the highest of all photomultiplier-coupled scintillation crystals and is usually defined as 100%, while the luminous efficiency of other scintillation crystals is expressed as a percentage of their luminous efficiency relative to NaI:TI.In addition to excellent luminescence, the crystal has high energy resolution, no self-absorption in the luminescence band, and it is easy to grow large-size crystals with low manufacturing cost, and large-size and shaped crystals can be obtained by hot forging process.

NaI:TI has been in use for more than 40 years since the early 1960s, and is widely used in petroleum geological exploration, nuclear medicine, high-energy physics, environmental monitoring, industrial CT, etc. During this time, it has not only not been replaced by new scintillation crystals, but also the demand has shown an overall upward trend over the years, and has always maintained its leading position in the production and usage of inorganic scintillation crystals.

NaI:TI single crystals are grown with NaI as the base material doped with appropriate concentrations of thallium, where the TI acts as the activating ion and becomes the luminescence center after absorbing the radiation energy. The crystal growth method is generally based on the Bridge-man method or the Czochralski technique.

Hot-forged NaI:TI crystals are formed by plastic deformation under certain temperature and pressure. Due to the continuous interaction and multiplication of dislocations, dislocation polygonalization and subgrain structure are formed, which improves the characteristics of the original single crystal that is easy to decouple along the surface, thus improving its resistance to temperature shock and mechanical vibration, while the scintillation properties are not affected.

In addition, the hot forging process makes it easier to produce crystals with complex geometries and large sizes, such as hexagons, rectangles, etc., as well as crystals longer than 200 mm.

Physical Parameters

Water absorption

At 0°C 100 ml of water can dissolve 158.7 g of sodium iodide, so the crystals are highly hygroscopic and susceptible to deliquescence. To avoid dampness, the crystals must be sealed in a metal box with an optical window for use.

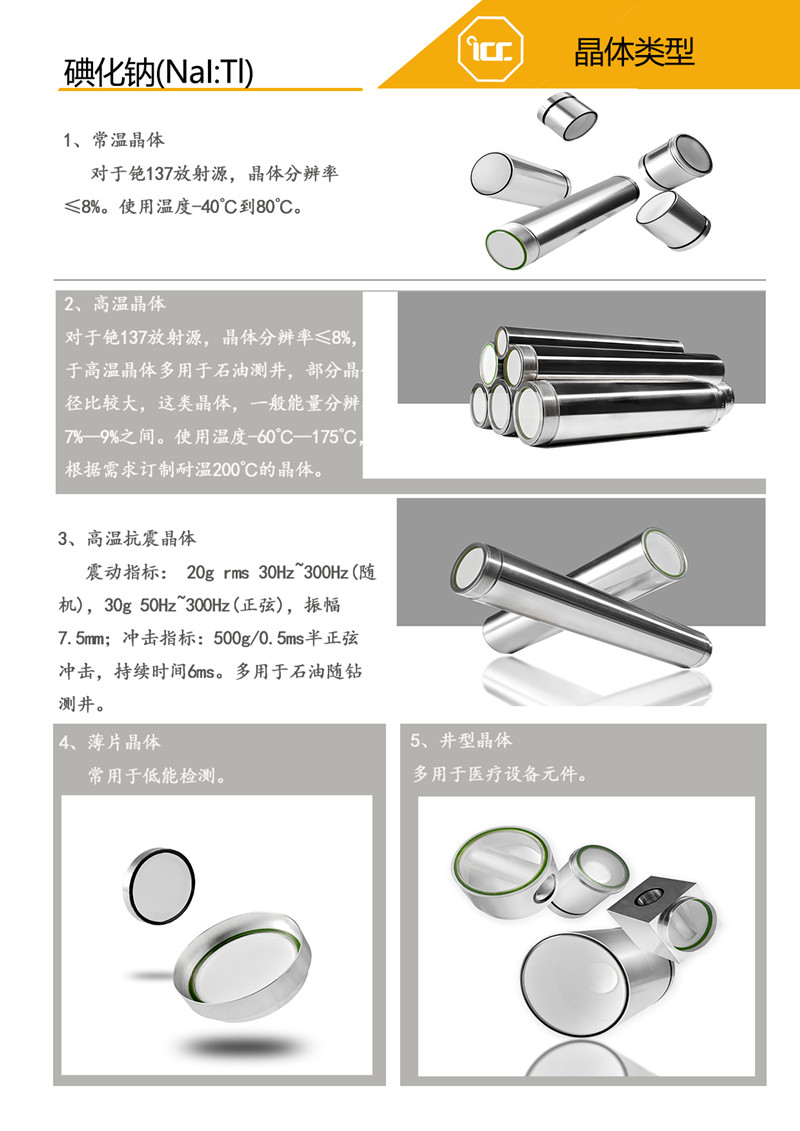

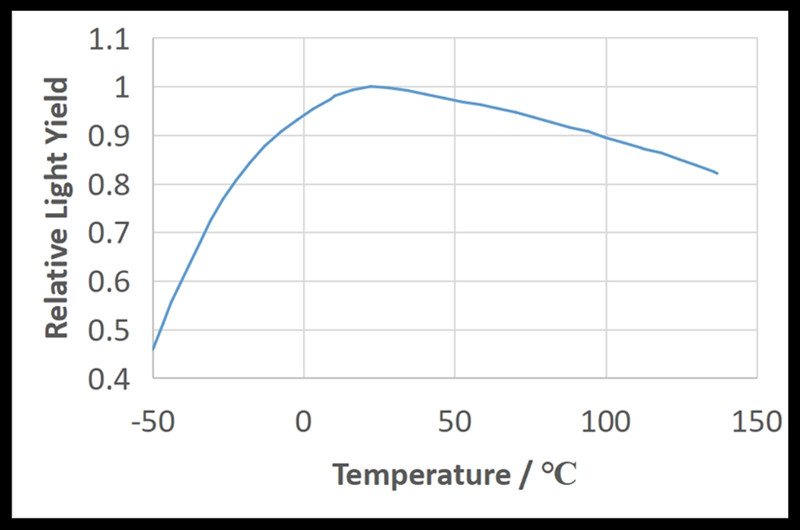

The light output of NaI:Tl scintillator is a temperature-dependent parameter

It reaches its maximum value at room temperature of 25°C and decreases as the temperature increases or decreases. In use, its light output will vary with ambient temperature conditions, as shown in Figure 1.

Figure 1 Light output curve of NaI:Tl crystal with temperature

Emission Spectrum

The luminescence spectrum of NaI:Tl scintillator shows that the luminescence reaches a maximum at 415 nm. The luminescence wavelength is related to the amount of activator and shifts slightly towards the long wave direction as the content increases.

Luminous efficiency

The luminous efficiency refers to the ability of the scintillator to convert the absorbed nuclear radiation energy into light, a parameter in scintillation performance testing is the light output. the light output of NaI:Tl crystals is the highest among all conventional scintillation crystals coupled with photomultiplier tubes, so it is often done as 100%. The luminous efficiency of the remaining crystals are expressed as a percentage relative to the NaI:Tl crystal.

Energy Resolution

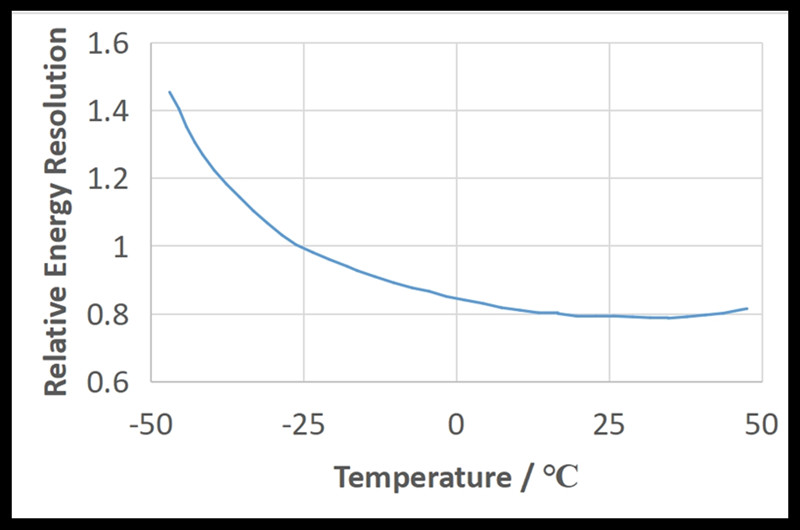

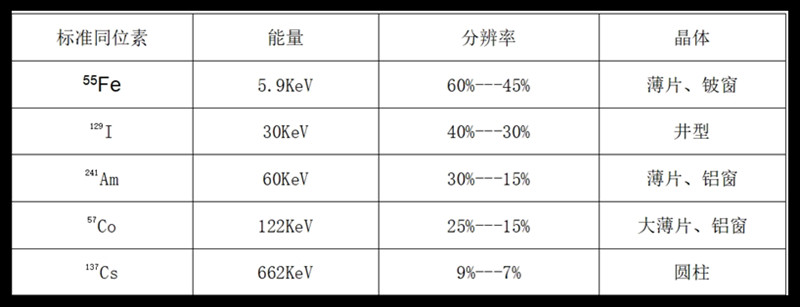

The energy resolution of NaI:Tl crystals is generally between 7% and 10% (for Cesium-137). Energy resolution is a measure of the scintillator's ability to resolve energy and is expressed as a percentage, the smaller the value the higher the resolution. The crystal aspect ratio has different requirements for different applications. As the crystal aspect ratio increases, the energy resolution decreases. Energy resolution is related to crystal quality (transparency, uniformity), crystal size, crystal shape, package quality, and operating temperature.

Figure 2 Energy resolution curve of NaI:Tl crystal with temperature

Table 1 Energy resolution of NaI:Tl crystals at different nuclides

Room temperature crystals

For Cesium 137 radioactive sources, the crystal resolution is ≤ 8%, and screening is required if within 7% is required. Use temperature -40℃ - 80℃.

High Temperature Crystals

For cesium source, the crystal resolution is ≤ 8%. Since high temperature crystals are mostly used for oil logging, some of them have a relatively large length diameter, for these crystals, the general energy resolution is between 7% - 9%. Use temperature -60℃--175℃, can be ordered according to the demand of temperature resistant 200℃ crystal.

High temperature shock resistant crystals

Vibration index: 20g rms 30Hz~300Hz (random), 30g 50Hz~300Hz (sine), amplitude 7.5mm; Impact index: 500g/0.5ms half-sine impact, duration 6ms.

Flake crystals

Commonly used for low energy detection.

Well-shaped crystals

Mostly used for medical device components

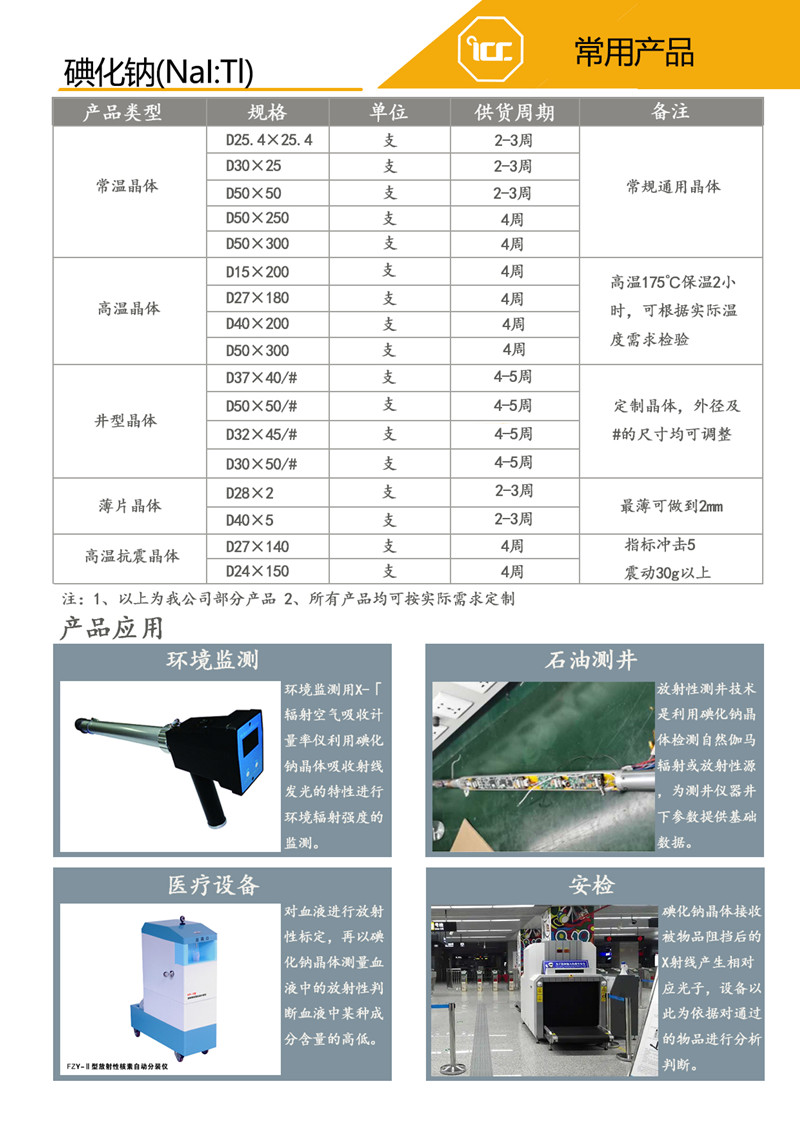

All-in-one probe

The crystal is directly coupled with the photomultiplier tube to improve the detection efficiency and can adapt to various usage environments.

Oil exploration field

For many years, NaI:TI crystals have been widely used in the field of oil exploration, mainly because of their excellent luminescence and small temperature effect. In nuclear logging, the crystal detector works at a depth of about 4000 meters underground and has to withstand the high temperature of 150~C~200℃ and certain shock vibration, so the scintillation crystal is required to have a high luminescence efficiency and a small temperature effect.

Crystals for environmental monitoring

This field is mainly for the industry to monitor the production, life, work environment, field nuclear radiation. The crystals used are small in size and do not require high temperatures, but they require high scintillation performance and sealing.

Crystals for Nuclear Medicine

Crystals for isotope therapy instruments: These crystals are smaller in size, but the processing is complicated (holes need to be punched in the longitudinal and transverse directions of the cylinder), and there are more scrap during processing, which requires higher processing equipment.

Crystals for industrial CT

Following the application of computed tomography (CT) technology in medical diagnosis, the development of industrial applications of CT technology has been remarkable.Compared with traditional methods such as ultrasound and radiography, industrial CT has fast detection rate, high resolution, and the measurement workpiece does not touch the measured part, and its work is not affected by the temperature, internal pressure or surface condition of the measured object, which can realize the non-damaging detection of the measured object.Industrial CT is moving into the fields of online real-time quality control of industrial production processes and online safety inspection of industrial equipment.For example: (1) Steel flow rate, thickness of steel plate and defect inspection in metallurgical industry. (2) Online and welding inspection of straight seam steel pipe, boiler welded pipe and spiral steel pipe. (3) Online inspection of automobile and motorcycle wheels and various parts. (4)Online inspection of tobacco industry strips. (5) pressure vessel online inspection. (6) rubber industry aircraft, automotive tires online inspection, etc. The technology has been widely used in national defense, metallurgy, petrochemical, machinery manufacturing, rubber and plastic industries.

Nuclear Physics

For a long time, detectors needed in nuclear physics research have mainly used NaI:TI.

Performance characteristics.

1. Because of the smaller temperature effect of NaI:TI crystals, the application in the field of oil exploration will continue to grow as the demand for extraction increases, and large size, high temperature resistance and shock vibration resistance are the development directions of NaI:TI scintillation crystals.

2.NaI:TI crystals will continue to grow in this field due to their high energy resolution and relatively low production cost.

3.Nal:TI will continue to be used in the field of nuclear medicine, especially for Y-camera crystals, because of the ease of obtaining high-quality, large-size crystals.

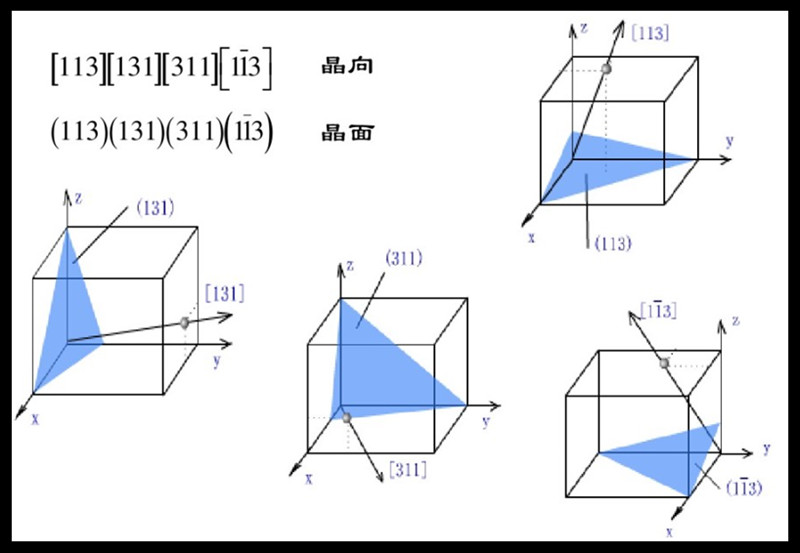

晶体定向知识-为何晶体要定向

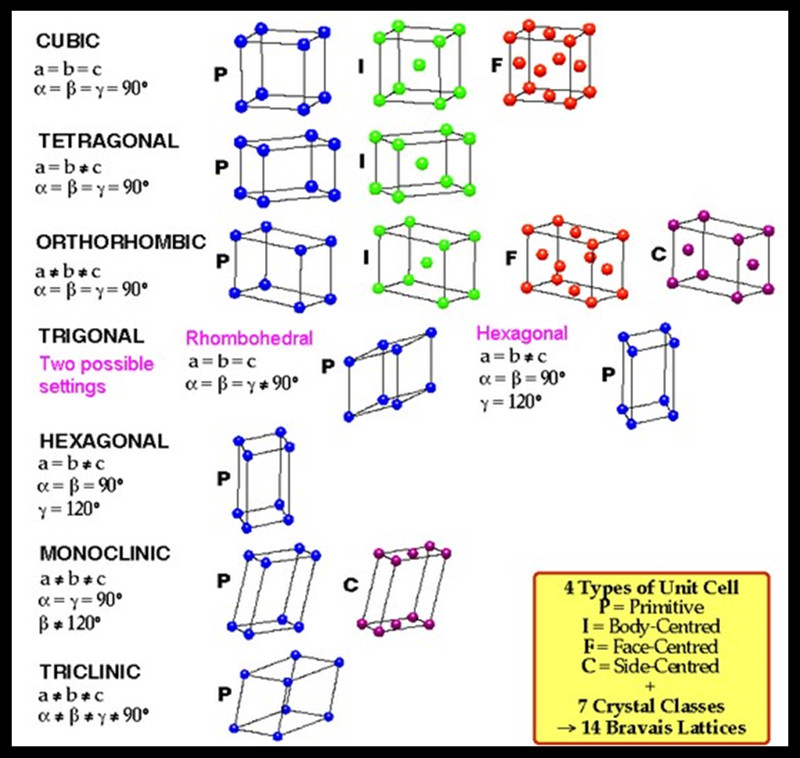

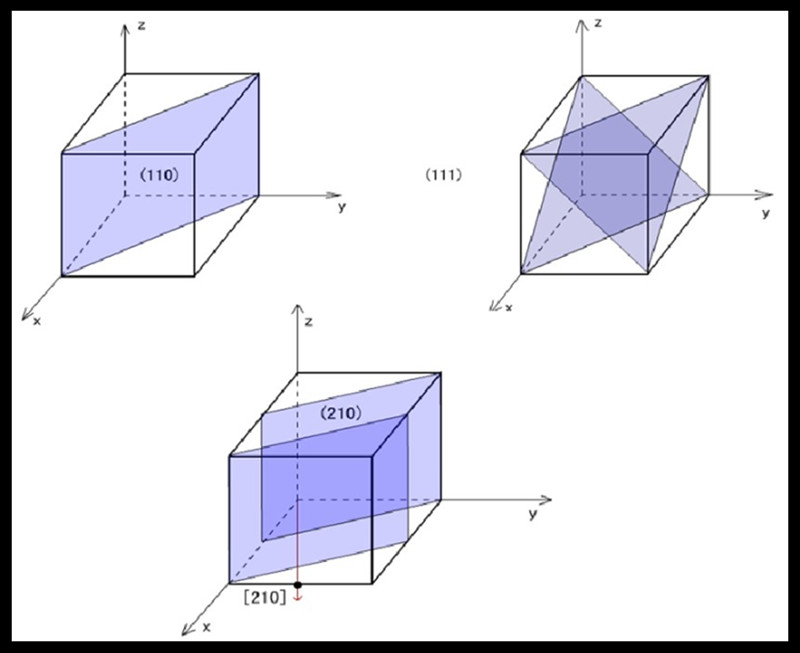

晶体结构即晶体的微观结构,是指晶体中实际质点(原子、离子或分子)的具体排列情况。自然界存在的固态物质可分为晶体和非晶体两大类,固态的金属与合金大都是晶体。晶体与非晶体的最本质差别在于组成晶体的原子、离子、分子等质点是规则排列的(长程序),而非晶体中这些质点除与其最相近外,基本上无规则地堆积在一起(短程序)。金属及合金在大多数情况下都以结晶状态使用。晶体结构是决定固态金属的物理、化学和力学性能的基本因素之一。

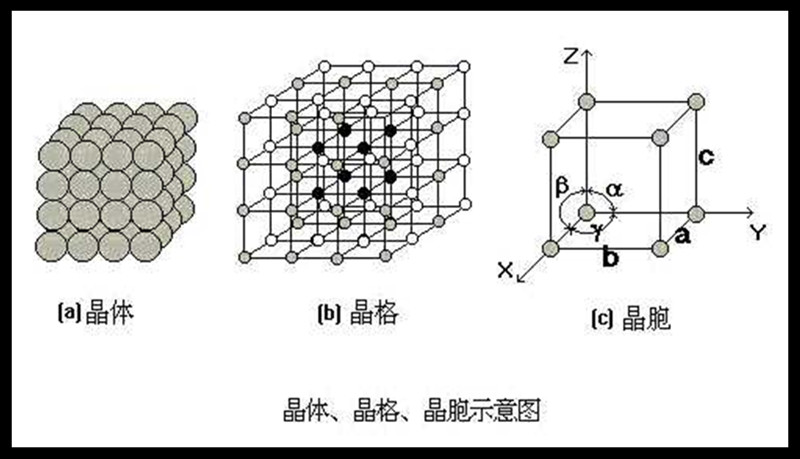

晶系

已知晶体形态超过四万种,它们都是按七种结晶模式发育生长,即七大晶系。晶体是以三维方向发育的几何体,为了表示三维空间,分别用三、四根假想的轴通过晶体的长、宽、高中心,这几根轴的交角、长短不同而构成七种不同对称、不同外观的晶系模式:等轴晶系,四方晶系,三方晶系,六方晶系,斜方晶系,单斜晶系,三斜晶系。

晶面

晶面指数(indices of crystal face)是晶体的常数之一,是晶面在3个结晶轴上的截距系数的倒数比,当化为整数比后,所得出的3个整数称为该晶面的米勒指数(Miller index)。六方和三方晶系晶体当选取4个结晶轴时,一个晶面便有4个截距系数,由它们的倒数比所得出的4个整数则称为晶面的米勒—布拉维指数(Miller Bravais indices)。以上两种指数一般通称为晶面指数

在晶体中,原子的排列构成了许多不同方位的晶面,故要用晶面指数来分别表示这些晶面。晶面指数的确定方法如下:

1.对晶胞作晶轴X、Y、Z,以晶胞的边长作为晶轴上的单位长度;

2.求出待定晶面在三个晶轴上的截距(如该晶面与某轴平行,则截距为∞)

3.取这些截距数的倒数,例如 110,111,112等;

4.将上述倒数化为最小的简单整数,并加上圆括号,即表示该晶面的指数,一般记为(hkl),例如(110),(111),(112)等。

晶向

晶向是指晶体的一个基本特点是具有方向性,沿晶格的不同方向晶体性质不同。布拉维点阵的格点可以看成分列在一系列相互平行的直线系上,这些直线系称为晶列。同一个格点可以形成方向不同的晶列,每一个晶列定义了一个方向,称为晶向。

标志晶向的这组数称为为晶向指数。

由于晶体具有对称性,有对称性联系着的那些晶向可以方向不同,但它们的周期却相同,因而是等效的,这些等效晶向的全体可用尖括号< α β γ >来表示。对于立方系,晶向[100]、[010]、[001]及其相反晶向就可以用<100>表示,其它晶系不适用。

立方晶系的晶向指数可用[uvw]来表示。其确定步骤为:

(1)选定晶胞的某一阵点为原点,以晶胞的3条棱边为坐标轴,以棱边的长度为单位长度;

(2)若所求晶向未通过坐标原点,则过原点作一平行于所求晶向的有向直线;

(3)求出该有向直线上距原点最近的一个阵点的坐标值u、v和w;

(4)将三个坐标值按比例化为最小整数,依次放入方括号[]内,即为所求晶向指数