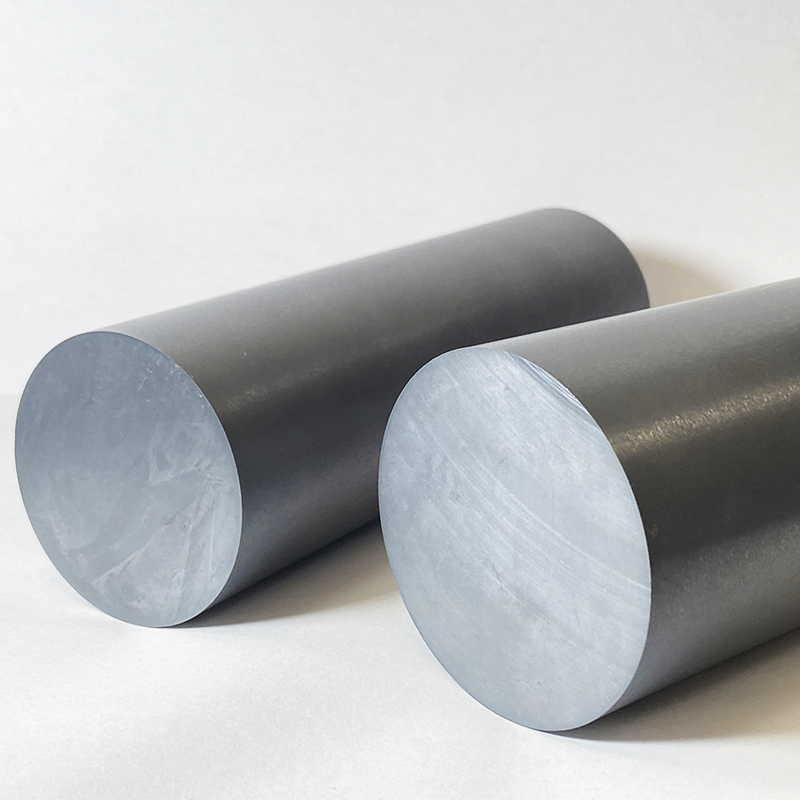

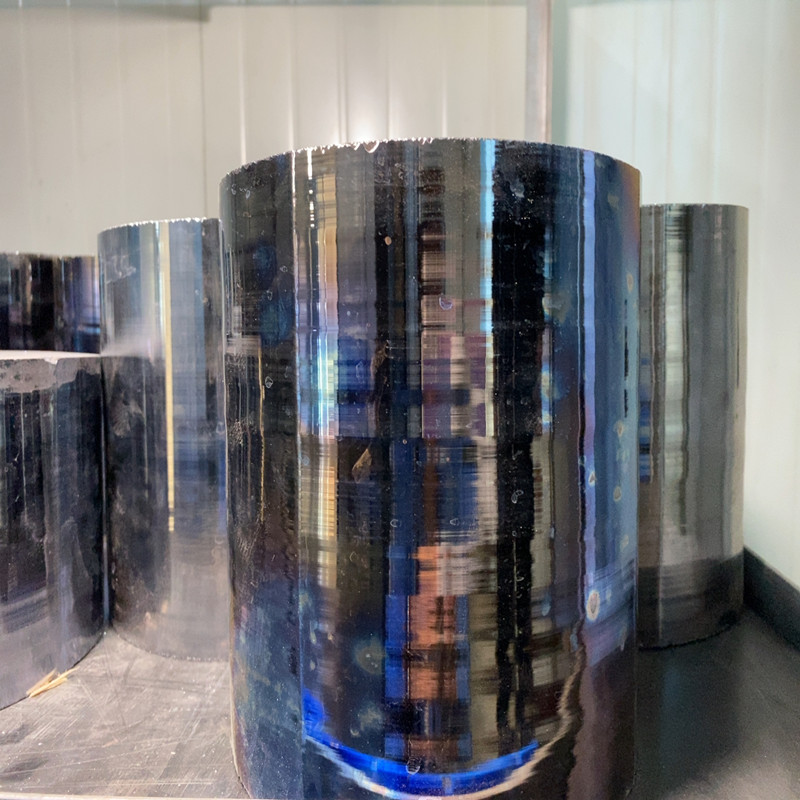

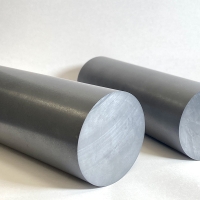

FZ-Silicon Crystals

Product Introduction:

FZ silicon crystals is grown by (Float Zone) felds.FZ silicon crystals are not in contact with the quartz crucible during the growing process,so there is less contamination during the growing process.FZ Silicon has many characteristics, such as lower carbon and oxygen content, fewer impurities, and higher resistivity, making it suitable for the manufacture of power devices and certain high-voltage resistant electronic devices.

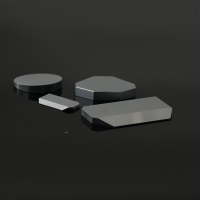

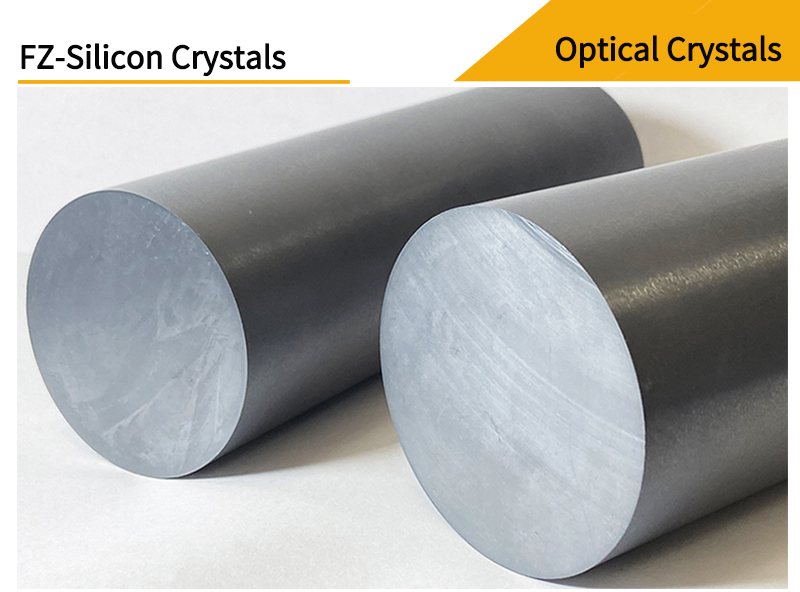

We can provide various specifications of FZ silicon blanks and finished products. The shapes of blanks include round, rectangular, drilled, windows, lens, galvanometer,shaped, etc.

FZ silicon crystals is grown by (Float Zone) felds.FZ silicon crystals are not in contact with the quartz crucible during the growing process,so there is less contamination during the growing process.FZ Silicon has many characteristics, such as lower carbon and oxygen content, fewer impurities, and higher resistivity, making it suitable for the manufacture of power devices and certain high-voltage resistant electronic devices.Our company can provide a wide range of FZ silicon wafers, blanks and finished products.

FZ silicon crystals is grown by (Float Zone) felds.FZ silicon crystals are not in contact with the quartz crucible during the growing process,so there is less contamination during the growing process.FZ Silicon has many characteristics, such as lower carbon and oxygen content, fewer impurities, and higher resistivity, making it suitable for the manufacture of power devices and certain high-voltage resistant electronic devices.Our company can provide a wide range of FZ silicon wafers, blanks and finished products.

Our company can supply many specifications of single crystal silicon blanks and finished products.The shape of the blank contains round, rectangular, drilled, windows, lenses, galvanometers, special shaped etc.

Our company can supply many specifications of single crystal silicon blanks and finished products.The shape of the blank contains round, rectangular, drilled, windows, lenses, galvanometers, special shaped etc.

Silicon has a high thermal conductivity and low density, making it suitable for making into laser mirrors. However, silicon is not suitable for CO2 laser transmission applications due to its strong absorption at 9 µm.

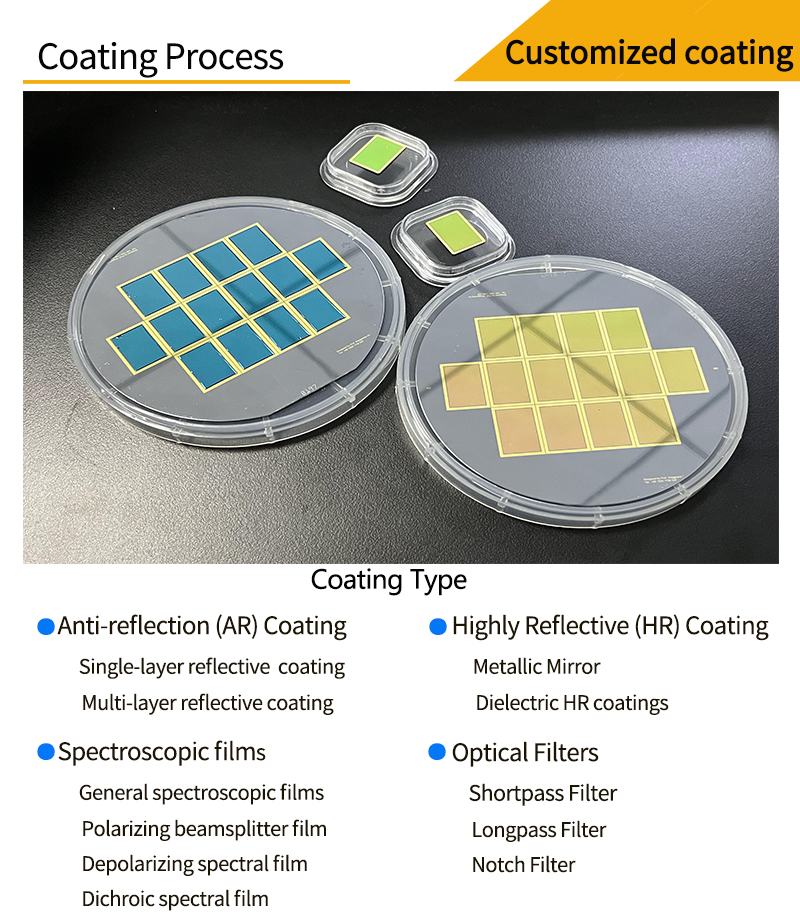

Coating refers to coating a transparent electrolyte film or metal film on the surface of the substrate material by physical or chemical methods. The purpose is to change the reflection and transmission characteristics of the material surface to reduce or increase the reflection, beam splitting, color separation, light filtering, polarization and other requirements.We can provide various optical coatings such as anti-reflective films, high-reflective films, spectral films, and metallic films. Broadband anti-reflective films are available for UV, visible, NIR and mid-infrared wavelengths.

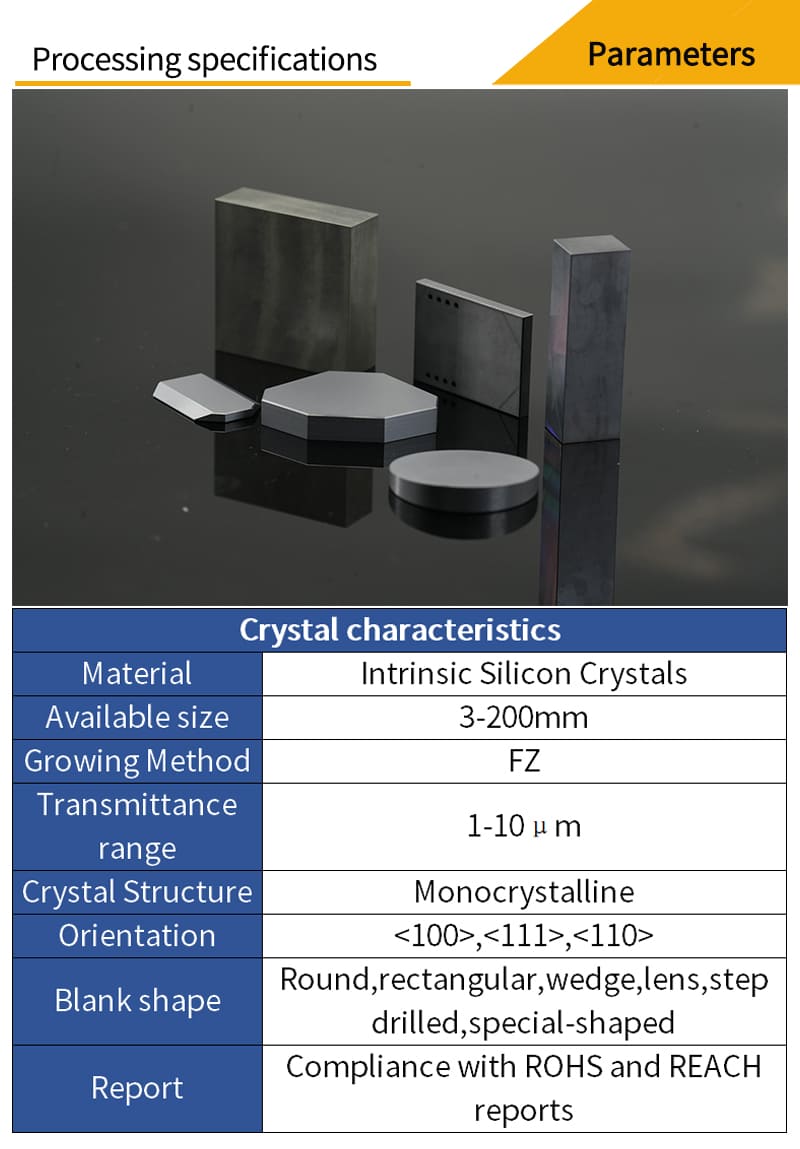

Material Standards

●Material: Silicon single crystal with a chemical composition of Si

●Purity: The purity of the raw material used for crystal growth should be not

less than 9N (99.9999999%) and the purity of the dopant used should be not

less than 5N (99.999%).

●Crystallization quality: silicon single crystal rods should have no mosaic, no

grain boundaries, no twin crystals.

●Dislocation density: The dislocation density should be no more than 100

dislocations/cm2.

●Conductivity type: Silicon single crystal conductivity type of a total of two

types: N type, P type

●The crystallographic orientation of silicon single crystals consists mainly of

the following crystallographic directions

●Resistivity: The resistivity of silicon single crystals is divided into four classes.

●Appearance quality: no pollution, no chipping, no cracks, no holes on the

surface of silicon single crystal

Transmittance test

●Samples

Monocrystalline silicon, diameter not less than 20 ~ 50mm, thickness 10 ± 0.5mm,through the polished surface finish to 80/50

●Test band

3μm~15μm

●Qualification requirements

T≥52.5%@3-5μm

●N-BK7

N-BK7 is the most commonly used optical glass for processing high quality

optical components,, with excellent transmittance from visible to near-

infrared wavelengths(350-2000nm), and has a wide range of applications in

telescopes, lasers and other fields. N-BK7 is generally chosen when the

additional benefits of UV fused silica (very good transmittance and low

coefficient of thermal expansion in the UV band) are not required.

●UV fused silica

UV fused silica has a high transmission from the UV to NIR (185-2100nm).

In addition, UV fused silica has better uniformity and lower coefficient of

thermal expansion than H-K9L (N-BK7), making it particularly suitable for

high power laser and imaging applications.

●Calcium fluoride

Due to its high transmittance and low refractive index within a wavelength

of 180nm-8um, calcium fluoride is often used as windows and lenses in

spectrometers and thermal imaging systems. In addition, it has good

applications in excimer lasers because of its high laser damage threshold.

●Barium fluoride

Barium fluoride have high transmittance from the 200nm-11um and they are

resistant to stronger high-energy radiation. At the same time, barium fluoride

has excellent scintillation properties and can be made into various infrared

and ultraviolet optical components. However, the disadvantage of barium

fluoride is that it is less resistant to water. When exposed to water, the

performance degrades significantly at 500℃, but it can be used for

applications up to 800℃ in a dry environment. At the same time, barium

fluoride has excellent scintillation properties and can be made into various

infrared and ultraviolet optical components.It should be noted that when

handling barium fluoride material, gloves must be worn at all times and

hands must be washed thoroughly after handling.

●Magnesium fluoride

Magnesium fluoride is ideal for applications in the wavelength range of 200nm

-6um. Compared to other materials, magnesium fluoride is particularly durable

in the deep UV and far IR wavelength ranges. Magnesium fluoride is a powerful

material for resistance to chemical corrosion, laser damage, mechanical shock

and thermal shock. It is harder than calcium fluoride crystals, but relatively soft

compared to fused silica, and has a slight hydrolysis. It has a Nucleus hardness

of 415 and a refractive index of 1.38.

●Zinc selenide

Zinc selenide has high transmittance in the 600nm-16um and is commonly

used in thermal imaging, infrared imaging, and medical systems. Also, due to

its low absorption, zinc selenide is particularly suitable for use in high-power

CO2 lasers. It should be noted that zinc selenide is a relatively soft material

(Nucleus hardness 120) and is easily scratched, so it is not recommended for

use in harsh environments. Extra care should be taken when holding, and

cleaning, pinching or wiping with even force, and it is best to wear gloves or

rubber finger covers to prevent tarnishing. Cannot be held with tweezers or

other tools.

●Silicon

Silicon is suitable for use in the NIR band from 1.2-8um.Because of its low

density, silicon is particularly suitable in applications where weight

requirements are sensitive, especially in the 3-5um . Silicon has a Nucleus

hardness of 1150, which is harder than germanium and not as fragile as

germanium.It is not suitable for transmission applications in CO2 lasers

because of its strong absorption band at 9um.

●Germanium

Germanium is suitable for use in the near-infrared band of 2-16um and is well

suited for infrared lasers. Due to its high refractive index, minimal surface

curvature and low chromatic aberration, germanium does not usually require

correction in low power imaging systems. However, germanium is more

severely affected by temperature, and the transmittance decreases with

increasing temperature; therefore, it can only be applied below 100°C. The

density of germanium (5.33 g/cm³) is taken into account when designing

systems with strict weight requirements. Germanium lenses feature a

precision diamond lathe turned surface, a feature that makes them well suited

for a variety of infrared applications, including thermal imaging systems,

infrared beam splitters, telemetry, and in the forward-looking infrared (FLIR)

field.

●CVD ZnS

CVD ZnS is the only infrared optical material, other than diamond, that

covers visible to long-wave infrared (LWIR), full wavelength and even

microwave wavelengths, and is currently the most important LWIR window

material. It can be used as windows and lenses for high-resolution thermal

imaging systems, as well as for advanced military applications such as

"tri-optical" windows and near-infrared laser/dual-color infrared composite

windows.